INSTALATION OF EXTERIOR DECORATIVE ELEMENTS

Selection of trims endings

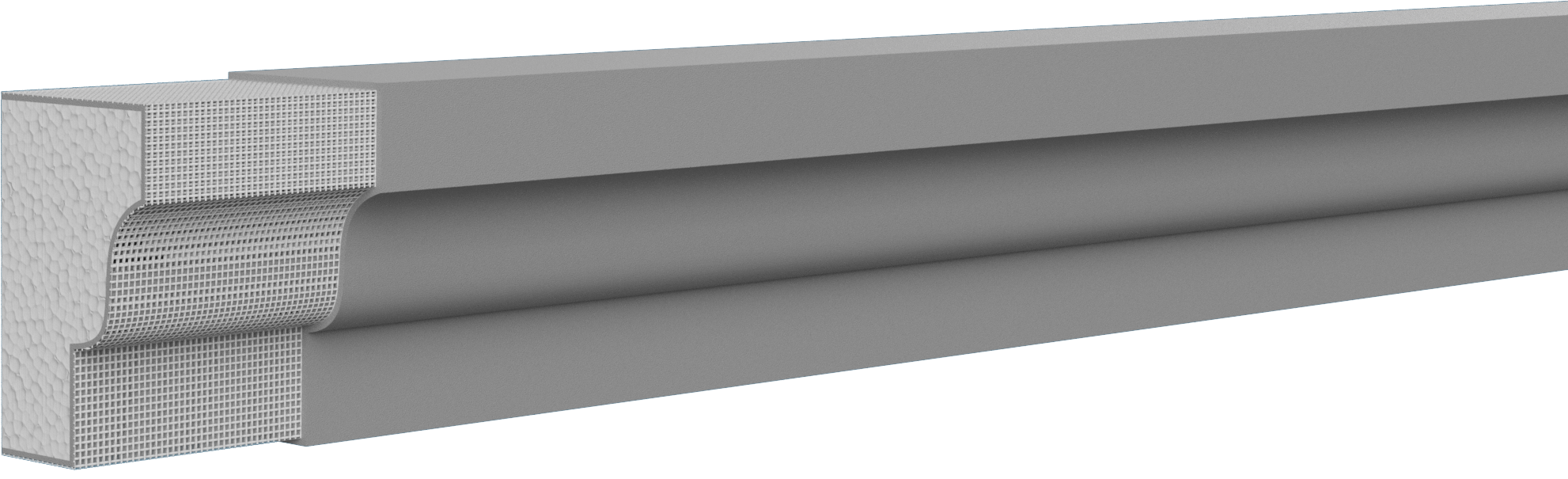

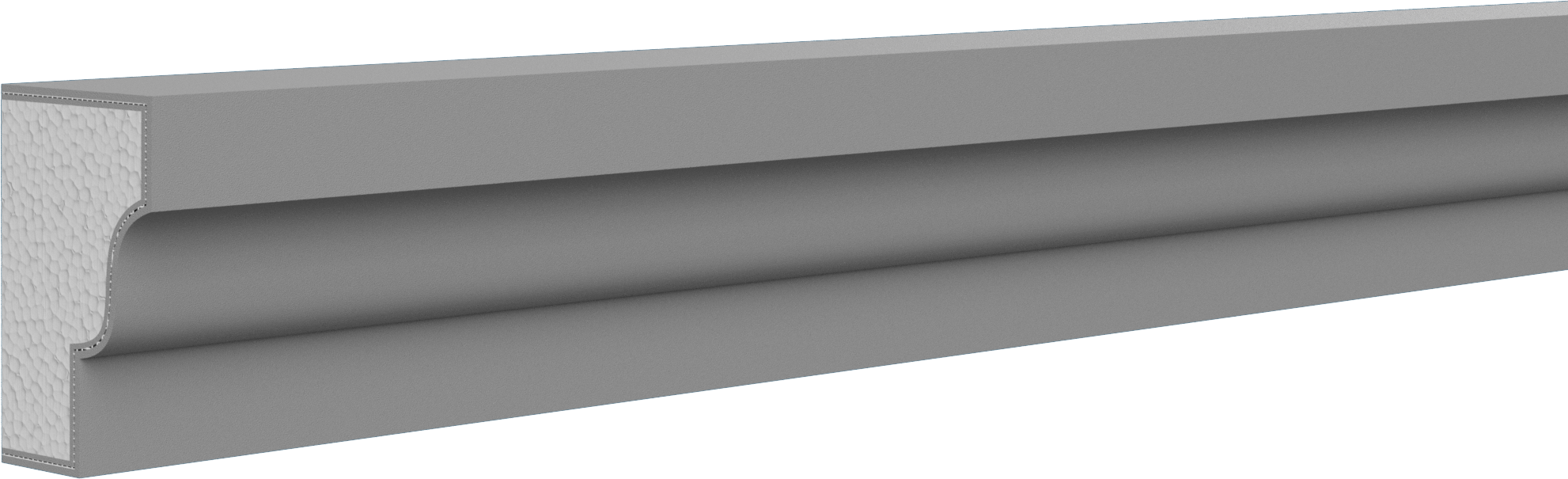

Depending on the project and to facilitate easier installation, we offer two options for the ends of facade trims: full trims or with chamfers at both ends. During production, 10 cm chamfers are left at the both ends of the products to allow the use of reinforcing fiberglass mesh tape at the joints before applying putty.

with chamfers at both ends

without chamfers

1. Preparation of surfaces for installation

Before starting, ensure surfaces are perfectly flat, addressing imperfections. Next, clean surfaces thoroughly to remove dust and debris, optimising conditions. Finally, confirm surfaces are dry for material adhesion integrity, ensuring professional results.

2. Preparation of products for installation

When preparing facade trims, usually measuring 2 meters in length, it is recommended to use concrete cutting disc saws to achieve the desired sizes. This process entails straightforward cutting, with no need for special or additional preparation; the focus is primarily on adjusting the trims to the required lengths.

3. Installation of products

Fiberglass Reinforced Cement composite coated products can be adhered using various types of adhesives: foam polystyrene cement adhesives, commonly used in building insulation systems, or polyurethane adhesives (e.g., Ceresit CT10).

4. Plastering of products

It is recommended to putty these gaps with cementitious base putties (e.g., Sakret BAK) at the connection points. For small gaps, joints, and gaps between surfaces of buildings and elements, we recommend using sealants (e.g., Bostik PU 2637) designed for exterior use.

5. Preperation of products for painting

Facade trims with a cement surface are sold without primer to make it easier to conceal joint seams. Once installed, the entire product is uniformly primed with deep penetrating primers designed for facades.

6. Painting of products

After priming, the product can be painted with water-resistant, oil-based, or epoxy paints that withstand atmospheric conditions. To achieve a coarser surface texture, additional priming with quartz primer or painting with textured paints before painting is possible.

7. Decoration of products (optional)

Facade trims can also be coated with textured plaster. For this purpose, it is better to use a special spraying machine.

Require more in-depth guidance for the installation of our product?